Keyboard Stabilizers Modification – The Ultimate Beginners Guide 2022

Are you looking to customize your mechanical keyboard to achieve your desired performance? Then look no further! In this article, I will share with you my method of lubing, modifying and tuning stabilizers, which is essential for the best possible build of your mechanical keyboard.

I will discuss the various methods available, and explain why I prefer the one I use for my stabilizer tuning.

But before Started I want to share the Best Kit that I utilize for Keyboard Modification

A Complete Kit for keyboard Stabilizer Maintenance

These stabilizers are designed for mechanical keyboards and come in two sizes: 2u and 6.25u. They are compatible with various keyboard layouts, including 61, 64, 87, 100, 104, and 108 keys. The set is transparent, allowing for a clean and unobtrusive appearance. Additionally, there are 84 buttons in total. These stabilizers are made of stainless steel, ensuring durability and stability for your keyboard.

Let’s get started!

It’s not a complex process, but yes with the right guidance and with the right tools, you can achieve it yourself. The main objective of tuning, lubing, or modifying these stabilizers is to eliminate any kind of rattling or unwanted noises that are caused by the stabilize. This is done by improving the fluidity motion of the components of stabilizers.

Also check other guides

How to Film a Switch on a Mechanical Keyboard Step By Step Guide | 2023

How to Test a Keyboard PCB: A Comprehensive Guide | 2023

A Complete Guide to Spacebar Dimensions

Stabilizers has 3 main components:

- Stabilizer bar

- Stabilizer insert

- Stabilizer housing

What are the Requirements to Tune Keyboard Stabilizers?

Stabilizers were basically designed to keep the keys balanced on the keyboard. A stabilizer that is not precisely made can be annoying by its irregular structure and failure to bounce back. All these problems can be eliminated by tuning the stabilizers.

“With the following attributes, the keyboard stabilizers can be more convenient”

A straight wire is right angled at the corner and all parts of the wire are co-planar. The ends of the wire are snapped just into the housing, without extra wobbling. The stem and housing are intact without any cracks or damage. The highest and the lowest points of the stabilizer are the same as the switch in the center.

How the Stabilizers can be Tuned?

Lubricating Stabilizers:

Friction between the contact points can damage the stabilizers, as every point in the stabilizers holds equal importance. Friction can damage these points in the long-term usage. Lubrication adds new life to the contact points by reducing contact points.

Wire:

Clicky sounds in a keyboard are caused by the wires that are not co-planer (not lying on the same plane). To check the co-planer put the wire on a completely flat surface. If the wire is not a co-planer bent it straight by hand or a pair of pliers.

Tuning the stabilizers requires patience and is time taking procedure but once it is done you will feel the convenience while working on the keyboard.

How to get started?

Lubricating a stabilizer is like adding a new life to it. This topic shows you lubrication can improve the keyboard speed and convenience. Modifying the stabilizer can make a significant difference in the performance of the keyboard.

To use this guide effectively you need to follow some preconditions. Beginners must have read our basic guide on how to lubricate the stabilizers to understand the basic terminologies. The list of tools and procedures are as under.

- Stabilizer set

- A pair of flush cutters

- Adhesive bandage

- Silicon grease

- Small paintbrush

- A pair of scissors

- Q – Tips

- Eye protection

- Small mirror

How to Solve the Binding Problem?

There are numerous problems that keyboard keys encounter, one of the common problems is binding. This problem can be solved by disassembling the stabilizer assembly and reinstalling them correctly.

To check the binding problem with the keys, you need a flat mirror and a light source. Pop the keys out and place them horizontally on the mirror. Hold them against a light source, if the keycaps are not straight the light will leak from the edges indicating the intensity of bowing. Repeat the whole procedure with the stabilizer wire, either straighten the wire or replace them.

Common Problems Observed with the Stabilizers:

- Excessive wobble

- Eliminating rattling sounds

- Stabilized keys are rough that makes a squeaking sound

- Bottom feels excessively spongy

1. Excessive Wobble:

Problem no 1 on the list that damages most of the stabilizers is excessive wobble. Excessive wobble can create inconvenience while working resulting in a drop in the typing speed and affecting efficiency.

There are following two ways to tackle this problem,

- Band-aid with adhesive bandage.

- Appling heat shrink insulations.

1.1 Band-aid with Adhesive Bandage:

Stabilizers wobble when there is a gap between the keyboard and the stabilizers. One who wants to avoid pain and effort should go for this solution. This method is used to fill the gap between them with the help of medical plaster. Use this method when you are certain that there is wobble in the stabilizer.

This method works best when the bandage or medical plaster used here is made of woven cloth that sticks well, lasts, and squeezes less.

How to do?

Follow these simple steps!!!

Take the dimension of the stabilizer,

Cut the medical bandage or plaster the size of the stabilizer.

Pierce holes for mounting the stabilizers.

Sticks these bandages on the mounting posts on the stabilizers.

- Start by locating the stabilizer that is causing the rattle.

- Cut a small piece of adhesive bandage or a band-aid to fit over the stabilizer.

- Carefully place the adhesive bandage over the stabilizer, making sure that it covers the area that is causing the rattle.

- Press down gently to ensure that the adhesive bandage sticks to the stabilizer.

- Repeat the process for any other stabilizers that are causing rattle.

- Test the keyboard to ensure that the rattle has been eliminated and that the adhesive bandage does not impede the movement of the stabilizers.

- If the adhesive bandage is too thick and affect the typing experience, you may remove the adhesive bandage and try a different solution.

1.2 Appling Heat Shrink Insulations:

Using this heat shrink method can bring improvement in the usage and convenience of the keyboard.

How to do?

- Start by preparing the heat shrink tubing by cutting it to the appropriate size for each stabilizer.

- Next, remove the stabilizer from the keyboard by carefully pulling it out.

- Slip the heat shrink tubing over the stabilizer, making sure that it is centered and straight.

- Use a heat gun or a hair dryer to carefully apply heat to the tubing, being careful not to overheat it.

- As the tubing shrinks, it will tightly conform to the shape of the stabilizer.

- Once the tubing has fully shrunk and cooled, carefully insert the stabilizer back into the keyboard.

- Repeat the process for each stabilizer.

- Test the keyboard to ensure that the stabilizers are functioning properly and that the heat shrink tubing does not impede their movement.

2. Eliminating the Rattling Sound in the Stabilizer:

Another problem with stabilizers is the rattle sound which can be very annoying while working. Rattle in the stabilizers is caused by friction. A solution to this problem is very simple, lubrication of stabilizer. The lubricant which I would recommend is silicon grease, it is a semi-transparent, white viscous paste made by mixing silicon oils with thicker. Besides being a good lubricant, it is also a corrosive inhibitor.

List of tools required:

‘a) Fine paint brush no 10 – 12.

‘b) Silicon grease 0.8 ounces.

‘c) A clean surface.

How to do?

Dip the end of the brush in silicon grease and put a thin layer of silicon grease on both ends of the wire including the tips. Don’t forget to lubricate the wire where it sits in the stabilizer.

Remember one thing, after lubrication, don’t put the stabilizer on a dusty or dirty surface as dust will stick to the grease and the problem will remain even after the whole process. When done with this reassemble the stabilizer carefully and enjoy the new comfortable movement of the stabilizer.

3) Stabilized Keys are Rough that Makes Squeaking Sound:

Friction is everywhere and stabilizers are no exception. After long continuous use of a keyboard, stabilizers start getting stuck and creates problem while working. Besides the stacking of the stabilizers, the squeaking sound while working fuels the problem. A solution to this problem is simple lubrication of the stabilizers. Some think this can be done by simply dipping the stabilizers in the silicon grease, this is a waste of the silicon grease and can create more problems.

List of tools required:

‘a) Cotton swabs.

‘b) Fine paint brush no 10 – 12.

‘c) A clean surface.

‘d) Silicon grease 0.8 ounces. (If you are looking for expensive lubricant use Krytox GPL 205 zero

grade.

How to do?

Use cotton swabs for cleaning the following main components,

‘a) Stabilizer bar.

‘b) Stabilizer insert.

‘c) Stabilizer housing.

Remove any dust and dirt using cotton swabs, if you are using any cleaner make sure the stabilizers are bone dry before proceeding further, then place them on a clean surface.

Using a brush and silicon grease apply a thin coat on the stabilizer bar and wipe off any excess silicon grease.

Apply a thin coat of silicon grease on the all inner sides of the housing, for better results avoid touching the housing by using a pair of tweezers so that all faces can be lubricated, keep them all on a clean surface to keep them from catching dirt again.

4) Bottom feels Excessively Spongy.

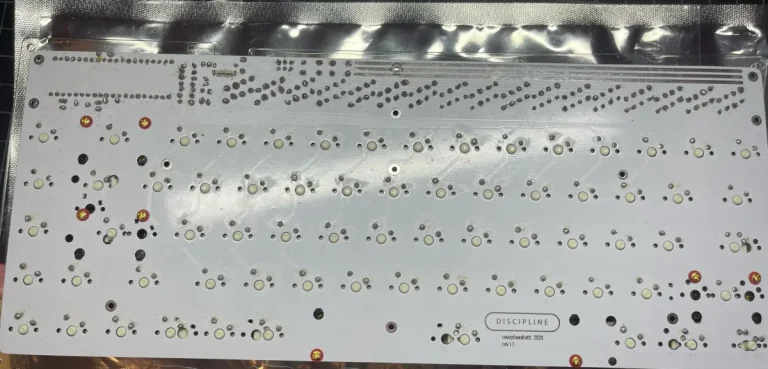

This problem creates a clear difference between the stabilized keys and the non-stabilize ones. The problem is caused by the pair of the legs under the key. Pictorial illustration of the problem follows for further clarification;

Solution to the problem is simply removing the pair of legs to make the base flat.

List of tools required:

‘a) Pair of flush cutters.

b) Sand paper (Not lower than 320/400 grit).

How to do:

1) Precisely identify the legs / part of the legs you are supposed to cut. Refer the picture below for further clarification,

2) After identifying simply cut with the pair of flush cutters, don’t forget the snib away the left over to make it as plain as you can.

3) Now use sand paper of 320 / 400 grit (as mentioned above) and rub the bottom of the key to remove leftover parts. Don’t use sand paper lower than 320 grit and don’t rub too much, other wise you will remove too much material from the key or make the bottom rough.

Make sure that before rubbing you precisely hold the key vertical to make the bottom perfectly flat.

After removing any or all of the problems you will notice a clear difference in the performance of the keyboard.

![How To Lube Switches Without Desoldering? Easy Lubing Keyboard Switches; Complete Guide [2022] 26 How to Lube Switches Without Desoldering? Easy Lubing Keyboard Switches; Complete Guide [2022]](https://clickyboard.com/wp-content/uploads/2022/07/fsfsdf3434-768x328-1.webp)