When choosing keycaps for your mechanical keyboard, the material composition plays a crucial role in determining your typing experience, durability, and long-term satisfaction. This comprehensive guide explores the fundamental differences between ABS (Acrylonitrile Butadiene Styrene) and PBT (Polybutylene Terephthalate) keycaps, helping you make an informed decision that aligns with your specific needs and preferences.

Quick Comparison: ABS vs PBT Keycaps

Understanding Keycap Materials: The Foundation of Your Typing Experience

What Makes ABS Keycaps Unique

ABS plastic represents the traditional choice in mechanical keyboard manufacturing, offering specific characteristics that have made it a staple in the industry for decades. This thermoplastic polymer combines three distinct chemical compounds: acrylonitrile provides chemical resistance, butadiene adds toughness and impact resistance, while styrene contributes to the material’s processability and surface finish.

The molecular structure of ABS creates a material that responds differently to manufacturing processes compared to other plastics. During injection molding, ABS flows smoothly into complex mold cavities, allowing manufacturers to create intricate designs with sharp details and precise tolerances. This manufacturing advantage translates into keycaps with crisp legends, smooth surfaces, and consistent wall thickness.

The PBT Advantage: Engineering Excellence in Keycap Design

PBT plastic represents a more advanced material choice, engineered specifically for applications requiring superior durability and resistance to environmental factors. As a semicrystalline thermoplastic polyester, PBT exhibits excellent dimensional stability, meaning it maintains its shape and size even under varying temperature and humidity conditions.

The molecular chains in PBT are more tightly packed than those in ABS, resulting in higher density and improved mechanical properties. This structural advantage manifests in several ways: increased resistance to deformation under stress, better retention of surface texture over time, and superior chemical resistance to oils and cleaning agents commonly encountered during keyboard use.

Tactile Experience: How Material Choice Affects Your Typing

Surface Characteristics and Long-Term Changes

The initial tactile experience between ABS and PBT keycaps reveals subtle but important differences. Fresh ABS keycaps typically feel smooth and slightly slippery under fingertips, with a surface that can be described as glassy or polished. This smoothness, while initially pleasant, undergoes significant changes with regular use.

Over time, ABS keycaps develop what enthusiasts call “shine” – a glossy, worn appearance that occurs as the surface becomes polished through repeated finger contact. This phenomenon happens because ABS has a relatively low glass transition temperature, making it more susceptible to surface deformation from the heat and oils naturally present on human skin.

PBT keycaps, in contrast, maintain a consistent matte texture throughout their lifespan. The surface feels slightly textured or gritty when new, providing better grip and finger traction during typing. This texture remains stable over years of use because PBT’s higher glass transition temperature and superior chemical resistance prevent the surface degradation that affects ABS.

Impact on Typing Performance and Comfort

The textural differences between materials directly influence typing performance and comfort during extended use sessions. The maintained grip of PBT keycaps can reduce finger slippage, potentially improving typing accuracy for users who type with high speed or intensity. The consistent surface also provides reliable tactile feedback, which many users find beneficial for touch typing.

ABS keycaps, particularly after developing shine, may feel less secure under fingertips, potentially affecting typing confidence. However, some users actually prefer the smooth feel of worn ABS, finding it comfortable for extended typing sessions. The choice often comes down to personal preference and typing style.

Durability Analysis: Long-Term Performance Considerations

Resistance to Physical Wear

The durability differences between ABS and PBT keycaps extend beyond surface appearance to fundamental structural integrity. PBT’s superior material properties translate into better resistance to physical wear patterns that develop over months and years of regular use.

Key wear areas include the contact points where fingers repeatedly strike the keycap surface, the sides where fingers may brush during typing, and the mounting points where the keycap attaches to the switch stem. PBT keycaps show significantly less deformation in these critical areas, maintaining their original profile and dimensions longer than ABS alternatives.

Chemical and Environmental Resistance

Environmental factors play a significant role in keycap longevity, and material choice determines how well keycaps withstand these challenges. PBT demonstrates superior resistance to UV radiation, meaning keycaps maintain their color and opacity even when exposed to direct sunlight or bright desk lamps over extended periods.

Chemical resistance also favors PBT, particularly important for users who regularly clean their keyboards or work in environments where keycaps might be exposed to cleaning agents, food oils, or other substances. ABS keycaps may show discoloration or surface degradation when exposed to certain chemicals, while PBT maintains its appearance and integrity.

Manufacturing Excellence: Production Processes and Quality

Injection Molding Considerations

The manufacturing process significantly impacts both the quality and cost of keycaps, with material choice playing a crucial role in production complexity. ABS’s lower melting point and excellent flow characteristics make it ideal for injection molding, allowing manufacturers to achieve fine details and consistent wall thickness with relative ease.

This manufacturing advantage enables ABS keycaps to feature sharp, precise legends and complex geometries at lower production costs. The material’s forgiving nature during molding means higher yield rates and fewer defective parts, contributing to the overall cost-effectiveness of ABS keycap production.

PBT’s higher melting point and different flow characteristics require more sophisticated manufacturing processes and tighter quality control. The material demands higher injection pressures and temperatures, along with longer cooling times, resulting in increased production costs but superior final product quality.

Double-Shot Molding Capabilities

Double-shot molding represents the premium manufacturing method for creating keycaps with legends that will never fade or wear away. This process involves injecting two different colored plastics in sequence, with the legend material forming the interior structure and the main keycap material forming the exterior shell.

Both ABS and PBT are compatible with double-shot molding, though each presents unique challenges. ABS’s excellent flow characteristics and wide processing window make it easier to achieve consistent results in double-shot production. The material bonds well with itself and other compatible plastics, creating strong, permanent connections between the legend and keycap body.

PBT double-shot molding requires more precise control of processing parameters due to the material’s narrower processing window and higher shrinkage rates. However, when executed properly, PBT double-shot keycaps offer superior durability and maintain their appearance longer than ABS alternatives.

Sound Characteristics: Acoustic Properties and Typing Feel

Material Density and Sound Dampening

The acoustic properties of keycaps significantly influence the overall typing experience, with material choice affecting both the pitch and volume of keystroke sounds. PBT’s higher density and different molecular structure create distinct sound characteristics compared to ABS.

PBT keycaps typically produce a deeper, more muted sound when struck, often described as “thocky” by keyboard enthusiasts. This sound profile results from the material’s ability to absorb and dampen vibrations more effectively than ABS. The denser structure reduces the transmission of high-frequency vibrations that contribute to sharper, more piercing sounds.

ABS keycaps tend to produce brighter, more resonant sounds with clearer high-frequency components. Some users prefer this acoustic signature, particularly when building keyboards intended for gaming or rapid typing, where the audible feedback helps confirm keypress registration.

Interaction with Switch Types

The acoustic interaction between keycap material and switch type creates complex sound profiles that vary based on the specific combination used. Linear switches paired with PBT keycaps often produce smooth, consistent sounds throughout the keystroke, while tactile switches may emphasize the bump sensation through modified acoustic feedback.

ABS keycaps can enhance the mechanical characteristics of certain switch types, particularly those designed to produce sharp, distinct sounds. The material’s resonant properties may amplify desirable switch sounds while also potentially emphasizing any unwanted switch noise or inconsistencies.

Cost Considerations: Value Proposition Analysis

Manufacturing Economics and Pricing

The price difference between ABS and PBT keycaps reflects not only material costs but also manufacturing complexity and market positioning. Raw PBT material costs more than ABS, and the more demanding manufacturing requirements further increase production expenses.

These cost factors typically result in PBT keycaps carrying a 20-50% price premium over comparable ABS alternatives. However, this initial investment often proves economical over time due to PBT’s superior durability and resistance to wear.

Long-Term Value Assessment

When evaluating keycap purchases, consider the total cost of ownership rather than just initial price. ABS keycaps may require replacement sooner due to shine development or wear, particularly for high-usage keys like space bars, enter keys, and frequently used letters.

PBT keycaps, while more expensive initially, often provide better long-term value through extended lifespan and maintained appearance. For users who type extensively or plan to keep their keyboards for several years, the additional investment in PBT often proves worthwhile.

Aesthetic Considerations: Visual Appeal and Design Options

Color Reproduction and Consistency

Material choice affects how colors appear and maintain their vibrancy over time. ABS excels in color reproduction, allowing manufacturers to achieve bright, saturated colors and precise color matching. The material’s characteristics enable vibrant translucent keycaps that work well with RGB backlighting systems.

PBT’s molecular structure can make achieving certain colors more challenging, particularly bright or saturated hues. However, PBT maintains its color consistency better over time, resisting the yellowing or fading that can affect ABS keycaps exposed to UV light or environmental factors.

Legend Quality and Durability

The method used to create legends (letters, numbers, and symbols on keycaps) interacts differently with each material. Laser etching, pad printing, and dye sublimation all produce different results on ABS versus PBT substrates.

Double-shot legends represent the premium option for both materials, offering permanent, wear-resistant characters that maintain their appearance throughout the keycap’s lifespan. PBT double-shot keycaps provide the ultimate combination of legend durability and material longevity.

Making the Right Choice: Decision Framework

Usage Pattern Analysis

Your typing habits and usage patterns should guide material selection. Heavy typists, programmers, writers, and gamers who spend long hours at their keyboards will benefit most from PBT’s durability advantages. The material’s resistance to shine and wear justifies the additional cost for high-usage scenarios.

Casual users, those who change keyboards frequently, or users prioritizing initial cost over long-term durability might find ABS keycaps perfectly adequate for their needs. The material’s excellent manufacturing characteristics ensure good quality at accessible price points.

Aesthetic Priorities

Consider your aesthetic preferences when choosing between materials. If you prioritize vibrant colors, RGB compatibility, or frequently change keycap designs, ABS might better suit your needs. For users who prefer subtle, professional appearances that maintain their look over time, PBT represents the superior choice.

Budget and Timeline Considerations

Evaluate your budget not just for initial purchase but for potential future replacements. If you plan to upgrade your keyboard setup within a year or two, ABS keycaps might provide sufficient quality for your timeline. For keyboards intended as long-term investments, PBT offers better value proposition despite higher initial costs.

Conclusion: Informed Decision Making

The choice between ABS and PBT keycaps involves balancing multiple factors including cost, durability, aesthetics, and personal preferences. Neither material is universally superior; each excels in specific applications and use cases.

PBT keycaps represent the premium choice for users prioritizing longevity, consistent feel, and professional appearance. The material’s superior durability and resistance to wear make it ideal for intensive use scenarios and long-term keyboard investments.

ABS keycaps offer excellent value for users seeking good quality at accessible prices, particularly when aesthetics, color options, or RGB compatibility are priorities. The material’s manufacturing advantages ensure consistent quality and enable creative design possibilities.

Understanding these fundamental differences empowers you to make an informed decision that aligns with your specific needs, usage patterns, and preferences. Whether you choose ABS or PBT, both materials can provide satisfying typing experiences when matched appropriately to your requirements and expectations.

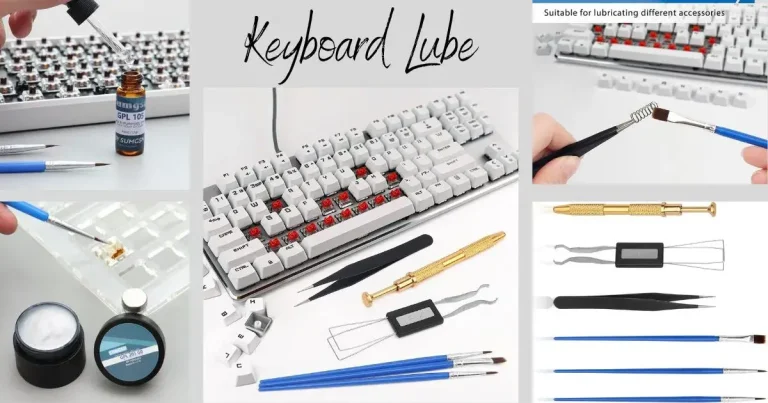

Remember that keycap material is just one component of your overall keyboard experience. The interaction between keycaps, switches, plate materials, and keyboard design creates the final typing experience, making it important to consider how your material choice fits into your complete keyboard setup.

![How to Lube Switches Without Desoldering? Easy Lubing Keyboard Switches; Complete Guide [2022] 6 How to Lube Switches Without Desoldering? Easy Lubing Keyboard Switches; Complete Guide [2022]](https://clickyboard.com/wp-content/uploads/2022/07/fsfsdf3434-768x328-1.webp)